About Nitor

Specializing in laser Manufacturing Services for Over 25 YEARS

OUR

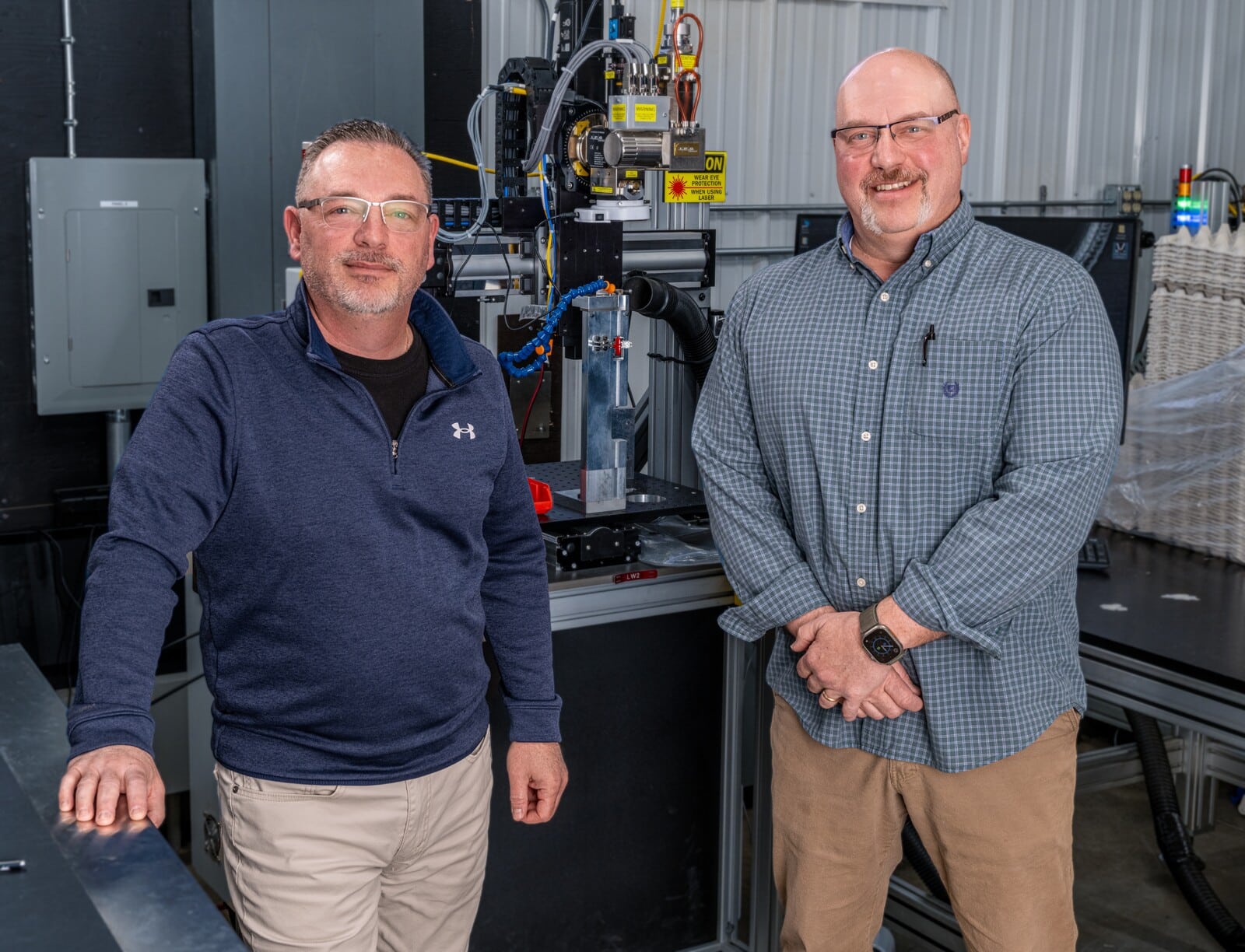

Nitor is a family-owned and operated company providing laser tube cutting, engraving, marking and laser welding services for military, aerospace, medical instruments, and other major machining industries across the country. Stephen and Todd Phillips started the business in 1996. Stephen is a Westfield State graduate and former History and Social Studies teacher. Todd is a WNEC Mechanical Engineering grad previously employed at Hamilton Standard. Both are still active members of the Massachusetts Air National Guard and proud veterans.

Nitor started in a 1200 sq. ft. space at Savage Arms in Westfield, MA. Special thanks to Ron Coburn for believing in Nitor when we had one laser and zero customers, and to the current shop guys, engineers, and top brass at Savage for remaining our most loyal customer all these years later. It would be remiss not to mention a special friend, Mr. Ron Lalli. Nitor owes a debt of gratitude to the former owner of Ebtec, Belt Technologies, Texcel, Litron, PTI and PTI overhaul. Ron’s guidance, persistence, and untiring support helped us throughout our journey. His selflessness (for he’s never asked for anything in return) to help fellow businessmen and women is an inspiration that won’t soon be forgotten.

Nitor excels in finding solutions for one-of-a-kind problems that save both time and money. Our unique and effective approach is reflected in the quality of work shown in our final product. Nitor’s work can be found from East to West in the United States, as high as on the International Space Station, and to the lowest depths of the sea, in U.S. submarines. Your product, with our laser expertise, takes on a personal sense of pride and accomplishment.