Special Projects

PROBLEM SOLVING SINCE 1996

ELEVATOR BUTTONS

Everyone has seen them, even touched them without much thought of how they come to be. Traditionally, the buttons are mechanically engraved, filled with black paint and sealed with clear lacquer. It is very labor intensive and expensive. Our customer came to us because they were looking for a faster, easier, and cheaper solution. Laser marking is done in a single step and produces a permanent, black mark that can be done with same day turnaround, saving them time and money in a “just-in-time” manufacturing world.

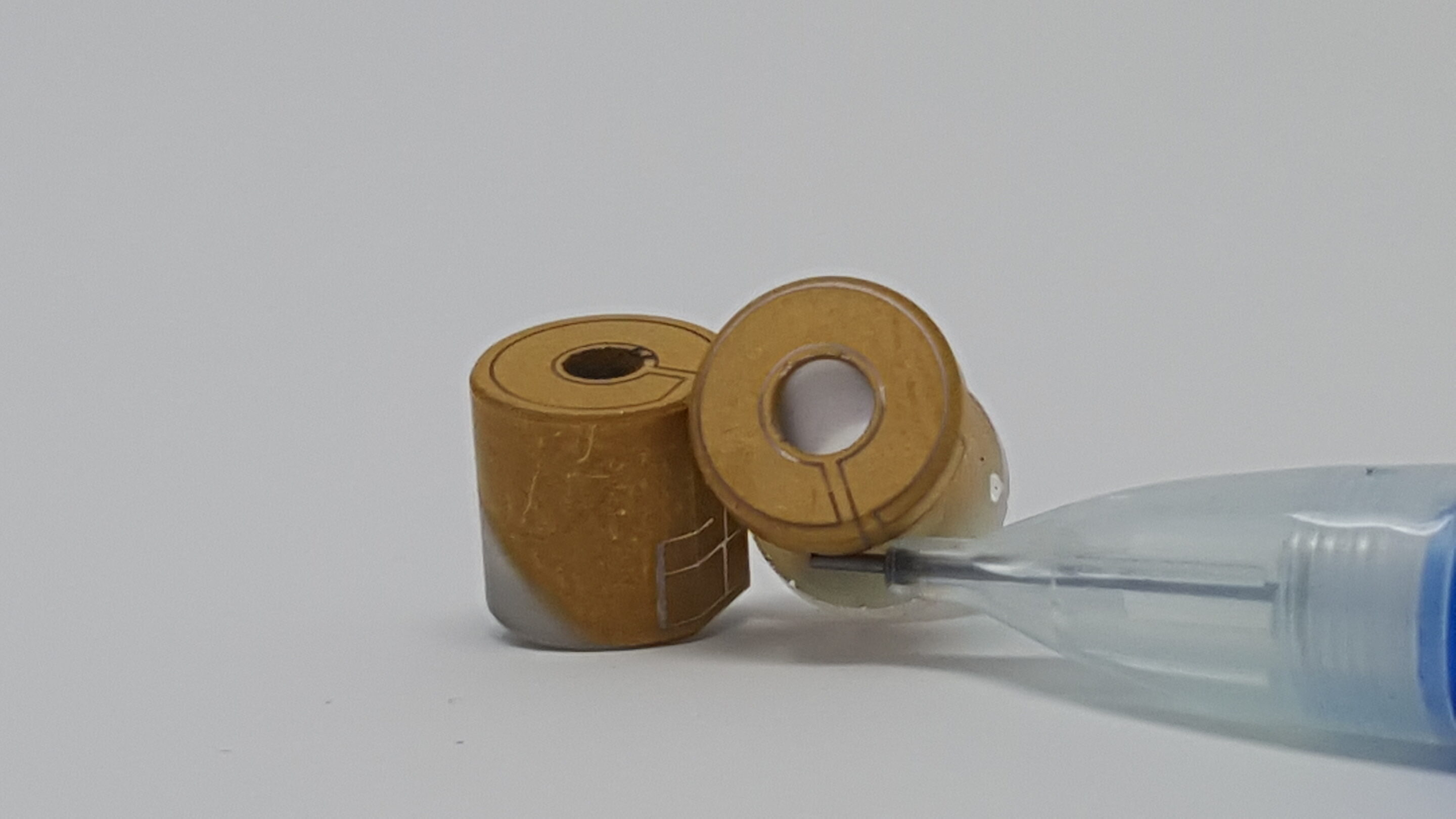

GOLD PLATED CIRCUIT

A Gold Plater came to Nitor with a unique problem. They needed to plate a ceramic spool, but they needed to leave a path for an electric circuit. Traditionally they would mask the area and then plate over the masking. The spool was too small and with too many contours to accurately mask what would later become an electrical circuit. Nitor was able to use a continuous beam and 5th axis technology to precisely laser ablate the electrical circuit.

REFLECTIVE BELT

Reflective surfaces are everywhere. From OSHA approved clothing to street signs and commercial carriers. One particular company had an issue with a foreign based competitor producing a reflective material similar to their own and passing it off as the U.S. based company. Nitor was tasked with embedding trademark nomenclature and trade-secret microscopic symbols that could positively identify the original and expose the knock-off product.

ABLATION

Nitor was an integral part in providing out-of-the-box laser solution when they solved a common problem in the adhesive bonding industry. The rib on top of a shotgun or rifle barrel is generally “glued” or adhered too with various epoxies. It cannot be welded due to warping of the barrel under intense heat. The adhesive bonding company was acid etching the mating surface of the barrel in order to gain a stronger adhesion. This is standard practice. The acid etching process was damaging the esthetics of the barrel if even the slightest amount were to leak out resulting in scrapping the entire part. Nitor was able to laser ablate the barrel itself in an incredible precise way resulting in a 100% compliance and work with engineers to develop surface variations that surpassed the customer’s pull tests with ease. The entire process was far faster and easier than the acid etching.

FREE ESTIMATES

Get a Quote Today

“We pride ourselves on providing fair pricing, quick turnaround times and solid customer service. With over 20 years in the industry, whatever your need, let Nitor make your mark.”